We recently finished painting a variety of parts for the Sycamore, a U.S. Coast Guard cutter based out of Cordova, Alaska. The project is an excellent example of how, when applied with care and precision, protective marine coatings extend the lifespan of valuable vessels exposed to harsh marine conditions.

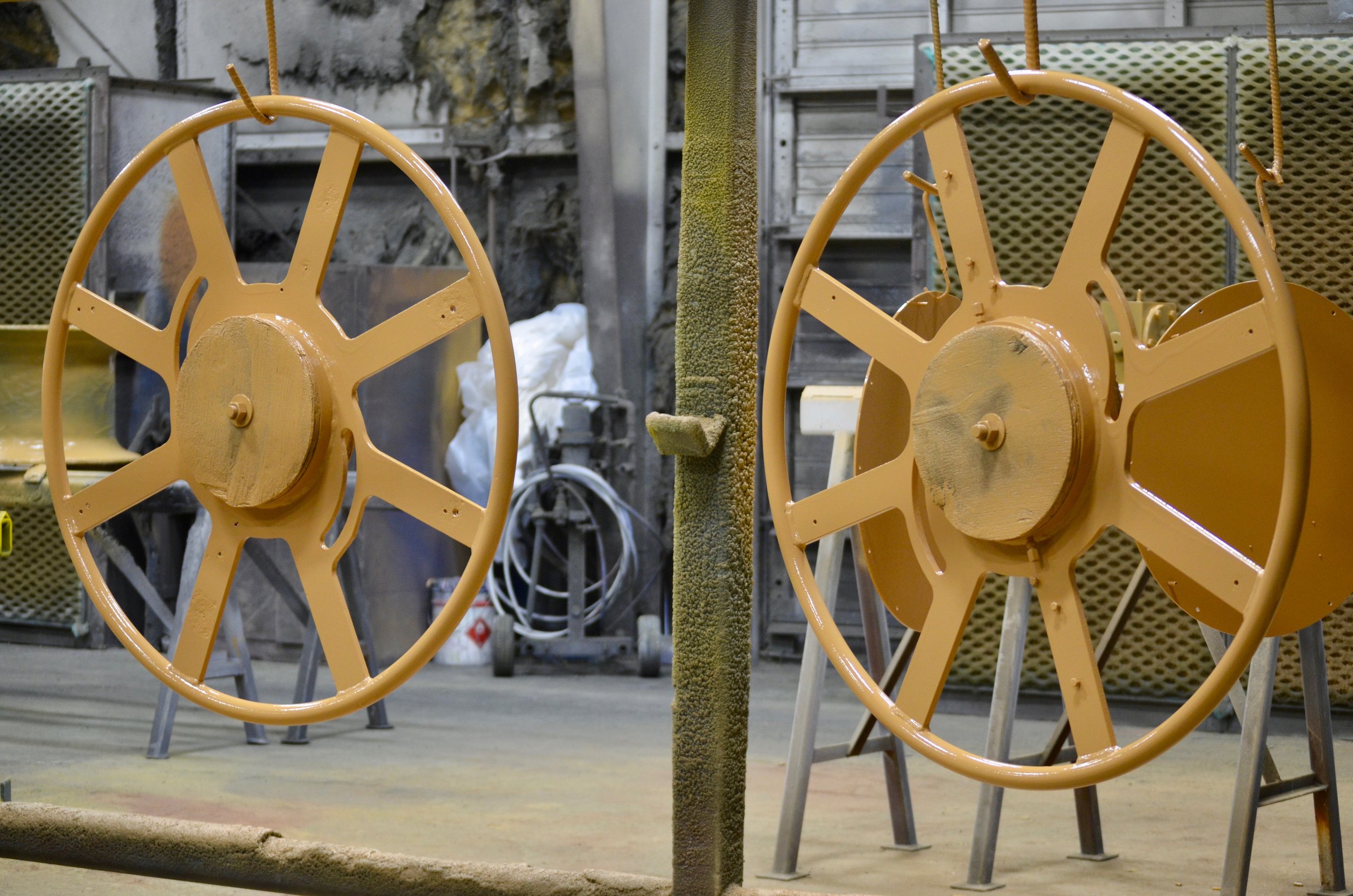

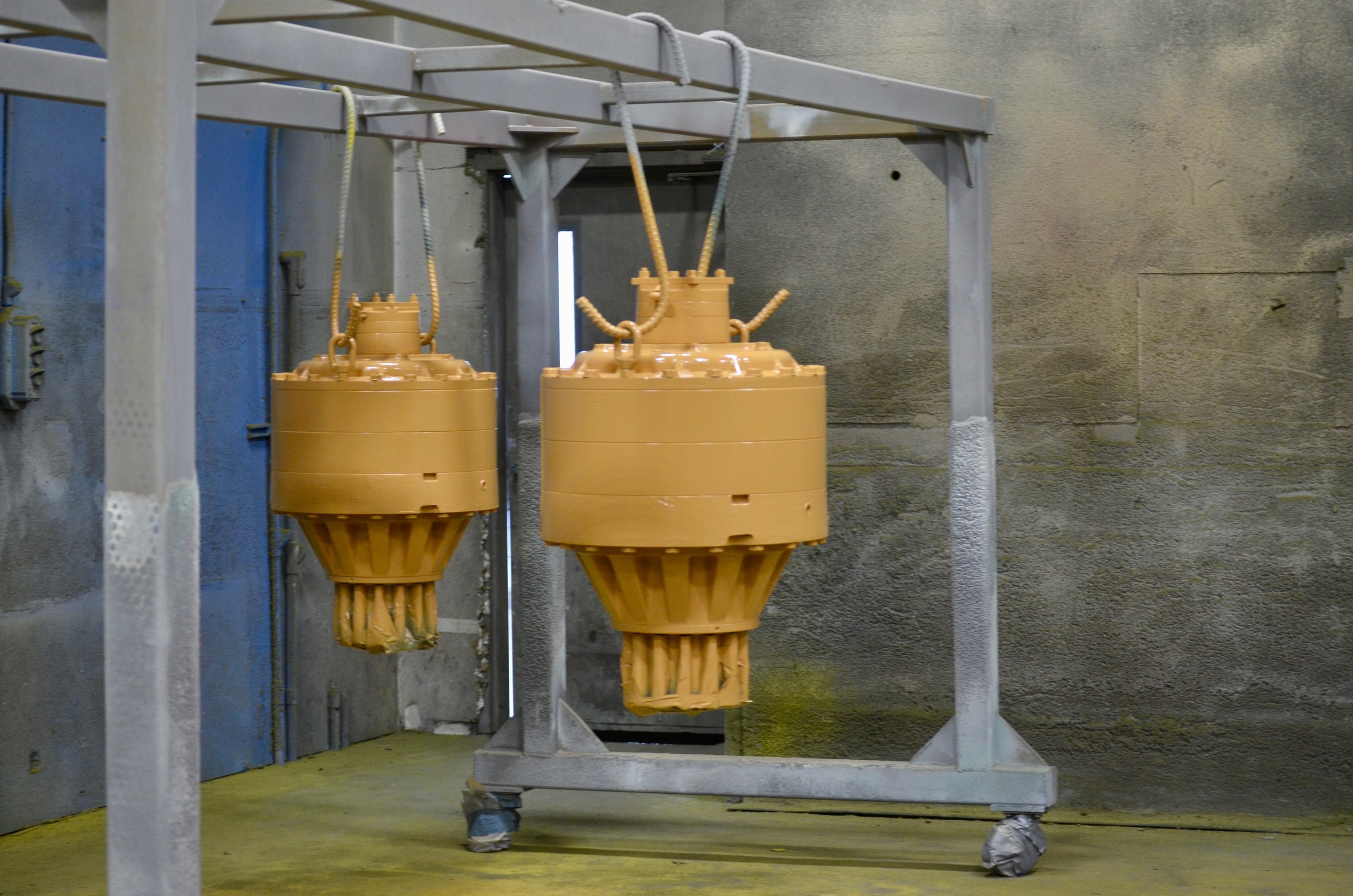

Sycamore ship part, “spar” beige coating in process

Meticulous work for the U.S. Coast Guard

This project involved blasting, prepping and coating approximately 50 different ship parts, including a large crane and several hydraulic components. Before we could begin coating, we spent a lot of time degreasing and carefully masking the parts to protect bearings, seals and cylinder rods. In addition to an inorganic zinc coating, we applied a PPG PSX 700 polysiloxane paint in a standard Coast Guard beige color known as “spar.”

As with our previous Coast Guard projects, this job was overseen by a Coast Guard inspector. He inspected the SP10 Blast, as well as each coat to ensure proper application and mileage.

A ship with many missions

The USCGC Sycamore plays many different roles for the U.S. Coast Guard. It is primarily a “buoy tender,” tasked with maintaining and replacing buoys used for navigation and collecting weather data. Additionally, the ship has been used for search and rescue missions, oil spill containment, and marine law enforcement. It has also served as an icebreaker, clearing the way for other vessels to pass through icy seas.

It was a pleasure to provide our services to the U.S. Coast Guard and be part of boosting the longevity of such an accomplished vessel.

Experience and efficiency

We’ve served as a resource for the marine industry for more than seven decades. This experience is what sets us apart.

Another key draw for marine companies is our ability to complete large, multi-part projects off-site efficiently. Marine businesses can ship deck equipment and parts/pieces from their crowded shipyards to our facilities where they’re sure the job will be done right. We then return the components to the customer completed and ready to install.

Serving the Pacific Northwest and Alaska, we’ve been applying marine coatings since 1945.