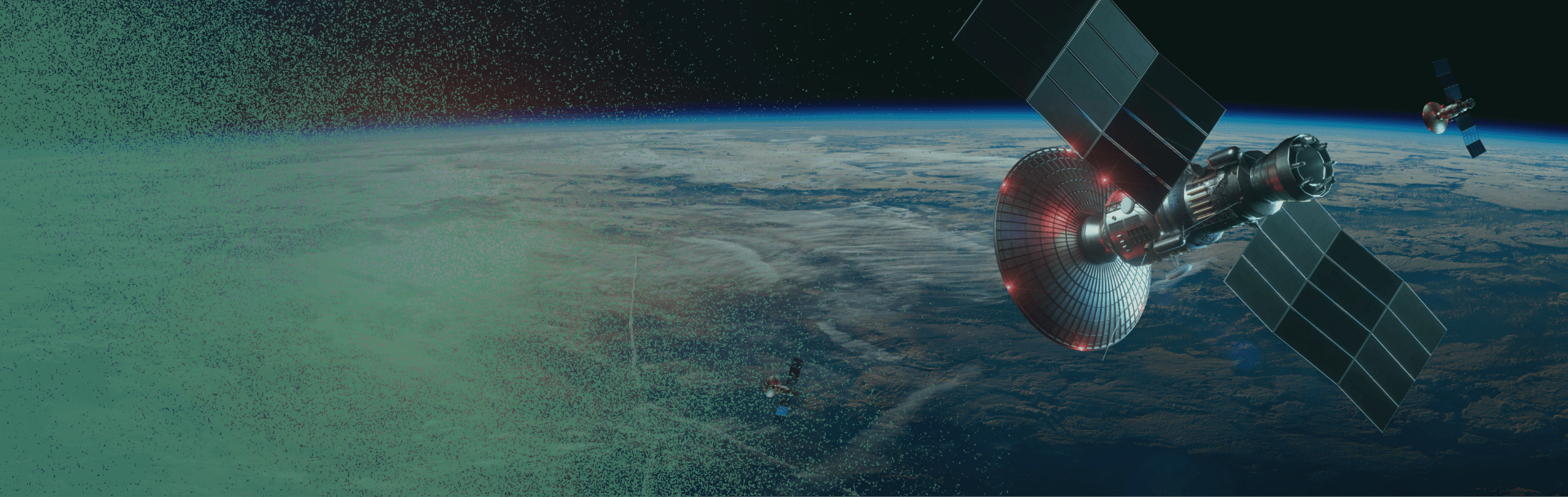

Covering Every Horizon

From the ocean floor, to outer space, we deliver precision coatings for ambitious projects across many pioneering industries.

We’re proud to be the Pacific Northwest’s trusted partner in coatings, now backed by ABW’s manufacturing expertise.

Industry Expertise

With decades of experience across a wide range of industries, we bring advanced technical knowledge to every project. As the nation’s leading coatings provider for LEO satellites, we set the standard for innovation and precision.

Marine

Architectural

Pipes & Utility

Food & Beverage

Aerospace

Nuclear

Defense

Energy

A Tradition of Excellence in Coatings and Beyond

For over eight decades, we've been industry leaders in steel preservation, offering protective coatings that extend the life of critical assets.

We specialize in developing custom coating systems tailored to meet key performance metrics. Our state-of-the-art facilities and highly skilled team allow us to deliver to the highest standards of performance.